ALTAROAD TopTrack, combine cost reduction and safety: a practical and simple solution for optimising your loads

10% reduction in transport costs

thanks to overload and underload alerts and real time load optimisation

Compact and adaptable

a dynamic weighing system quickly deployable at any site and with no impact on traffic

Safety and compliance

ensure traceability of site flows and prevent overloading

The ALTAROAD platform is completed by a mobile and dynamic weighing system, TopTrack. Coupled with a camera, our solution allows you to optimise your loads and save time, costs, and personnel.

Detection of the vehicle and its load in movement:

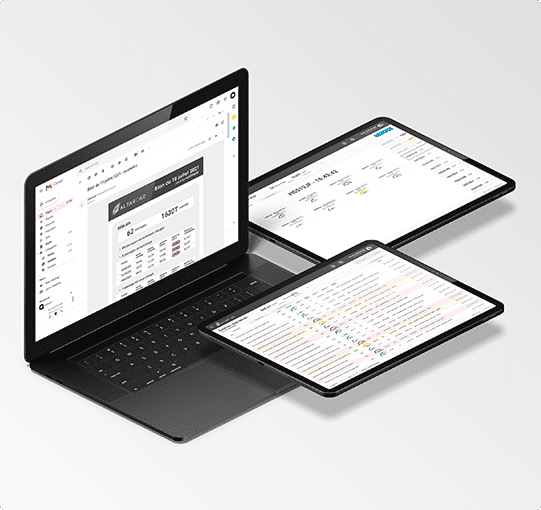

Collected data transmitted and analysed in real time:

Alerts – customisable indicators available on our interface for efficient decision-making:

Reduction of the number of rotations and transport costs:

Detection of overloads by type of vehicle:

Automatic generation of waste tracking notes with the correct vehicle mass

“Optimising our truck loads can save you between 5 and 10% on transport costs.“

A compact and mobile weighing system:

Does not require a lot of space nor support:

Directly connected to the platform without specific development

Thanks to ALTAROAD’s DigiTrack platform, TOPTRACK can be easily integrated with management systems using standard APIs